PLC signal transmission

The space is very small

Ultra short cable channel

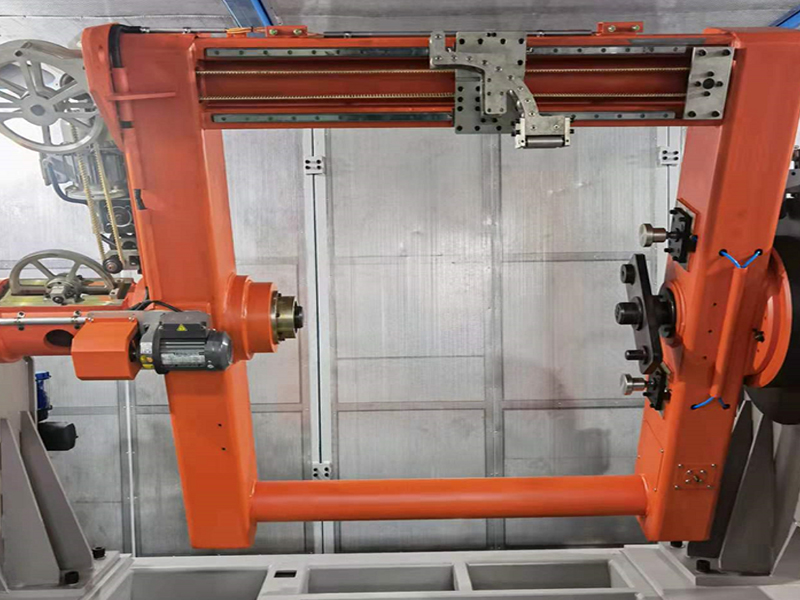

Automatic refueling lubrication system

Automatic bearing temperature sensing system

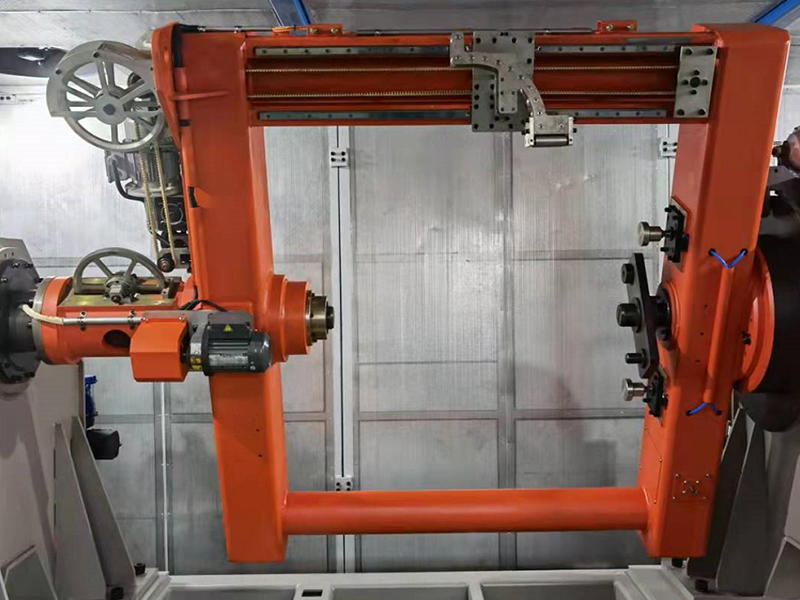

Energy saving of variable frequency motor 20%

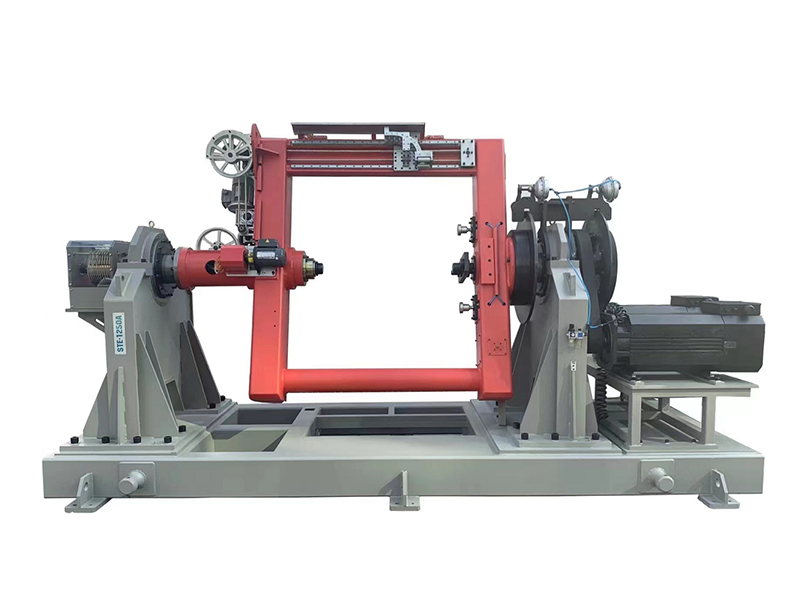

The whole machine adopts individual motor control

Advanced aerodynamic design

Variable frequency motor and control system

NSK bearing, high tensile strength

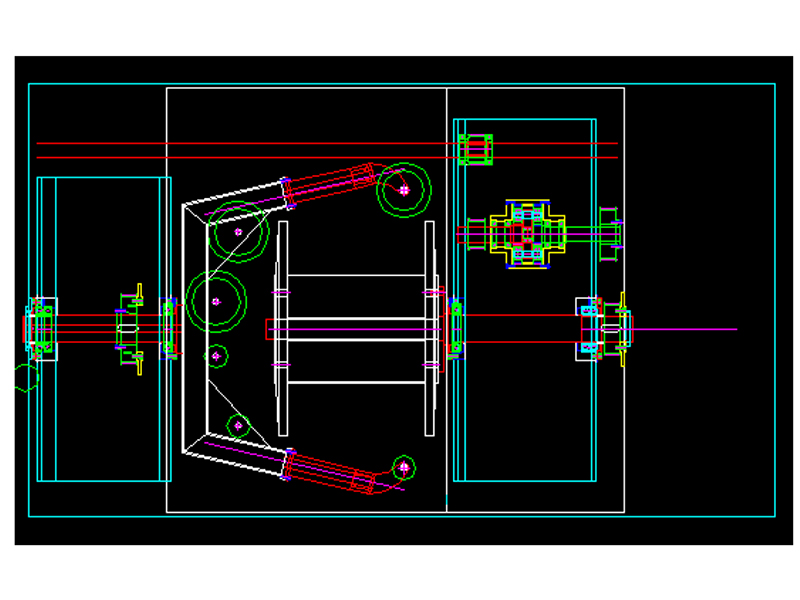

Excavation free foundation and convenient installation

The smart meter is installed in the control cabinet

Application:

This machine set is applicable to the high-speed cable forming and twisting of all kinds of power cords, PVC and PE cables, Category 5, 6, and 7 data cables, telecommunication cables, and other special-purpose wires and cables. It can also be used for central taping and side taping.

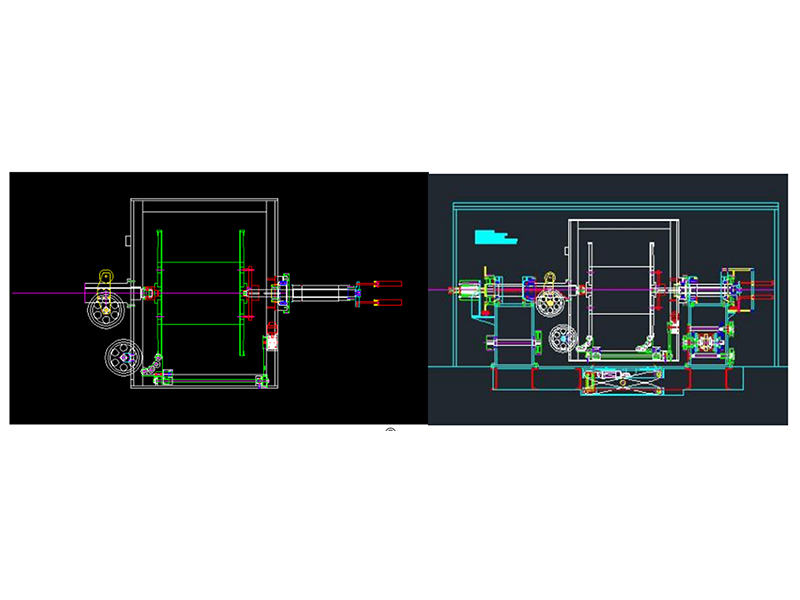

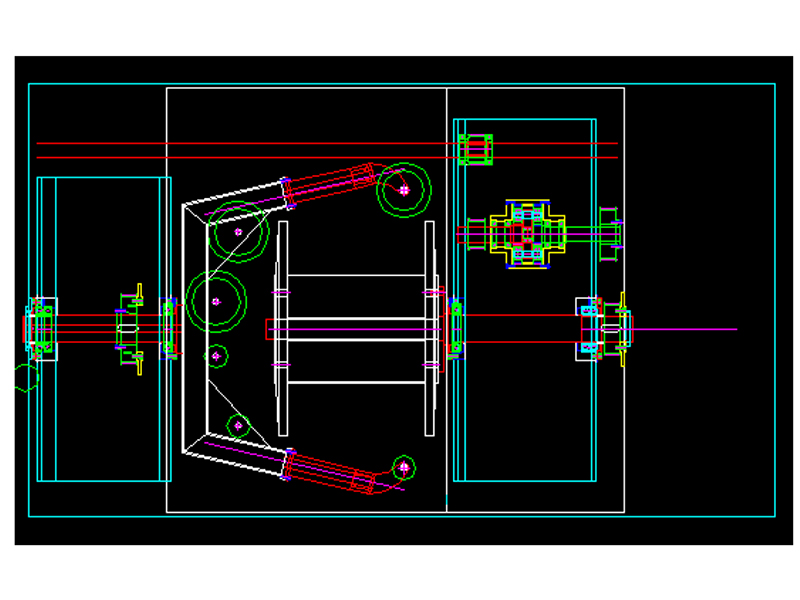

Equipment composition

| No. | Description | Quantity | Remarks |

| 1 | Ø560/630 motor driving pay off (frame type) | 7 sets | |

| Ø560/630 motor driving pay off (Cantilever type) | 7 sets | Optional | |

| 2 | Die holder | 1 set | |

| 3 | Pneumatic wire clamping device | 1 set | |

| 4 | Central type taping machine | 2 sets | |

| 5 | Longitudinal Taping machine | 1 set | |

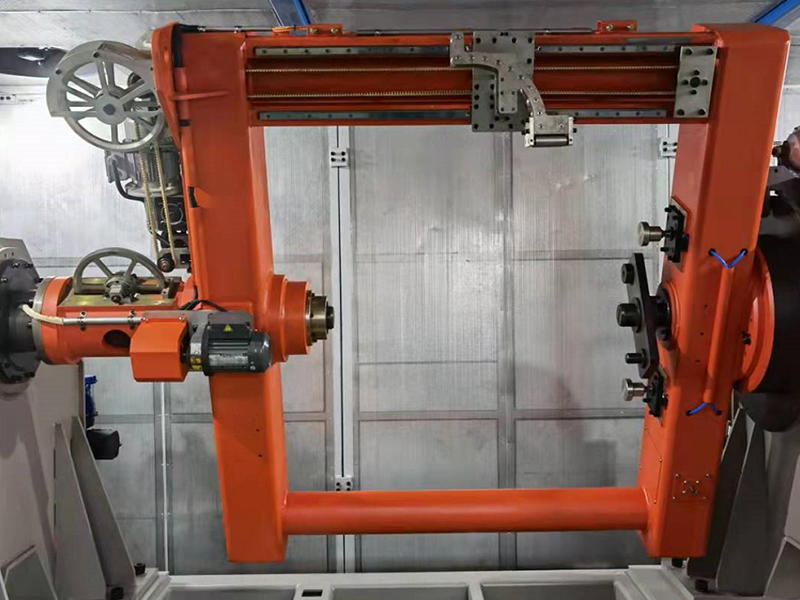

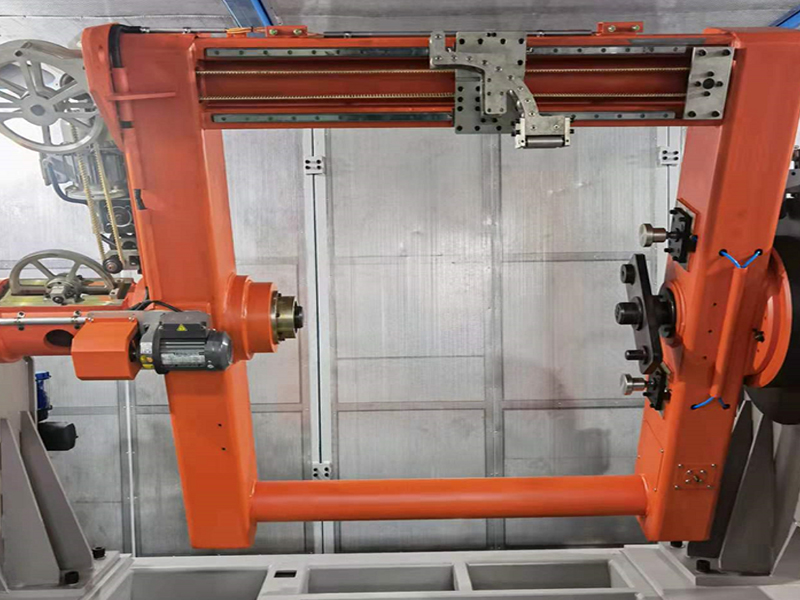

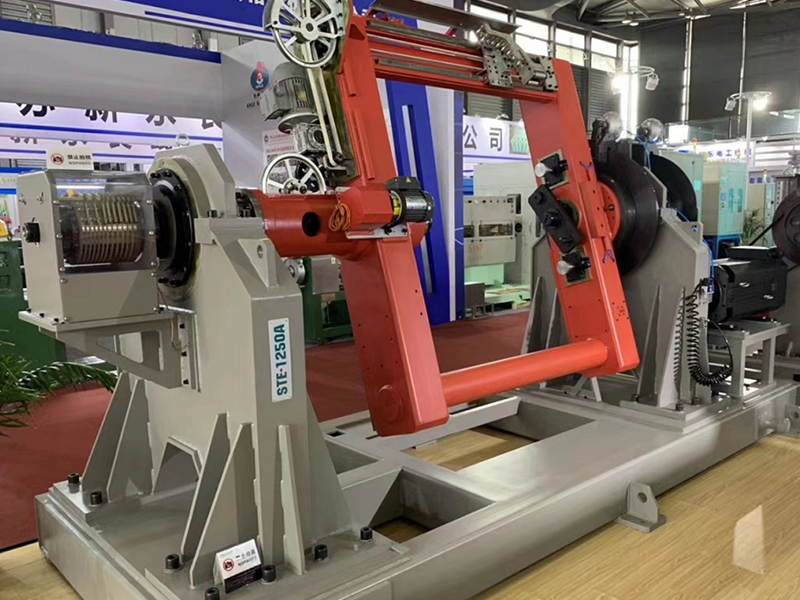

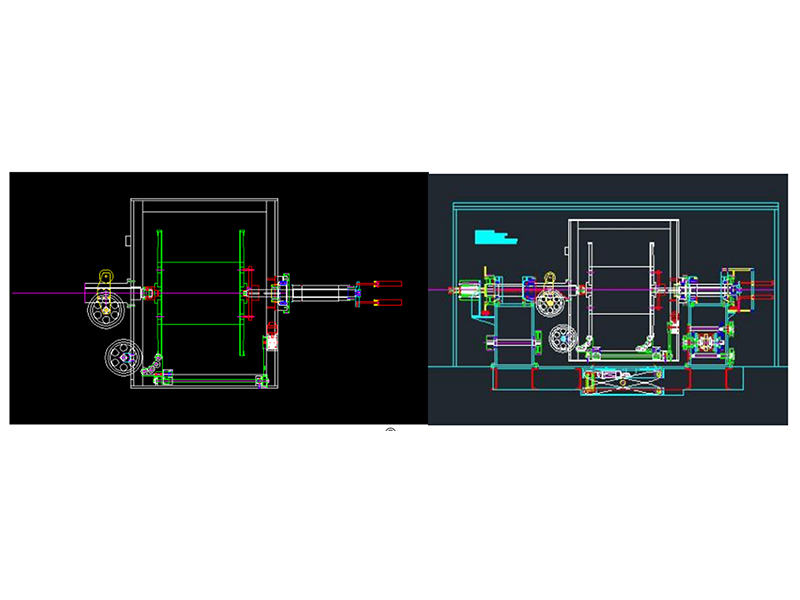

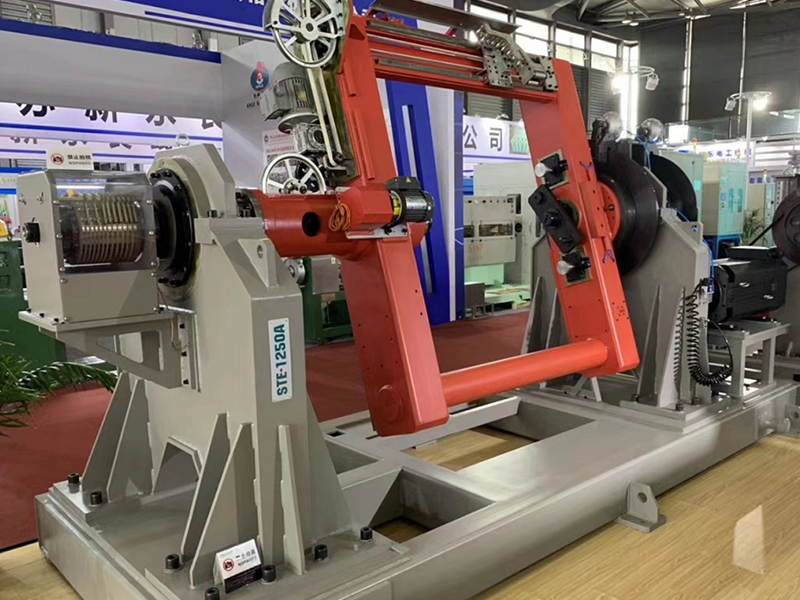

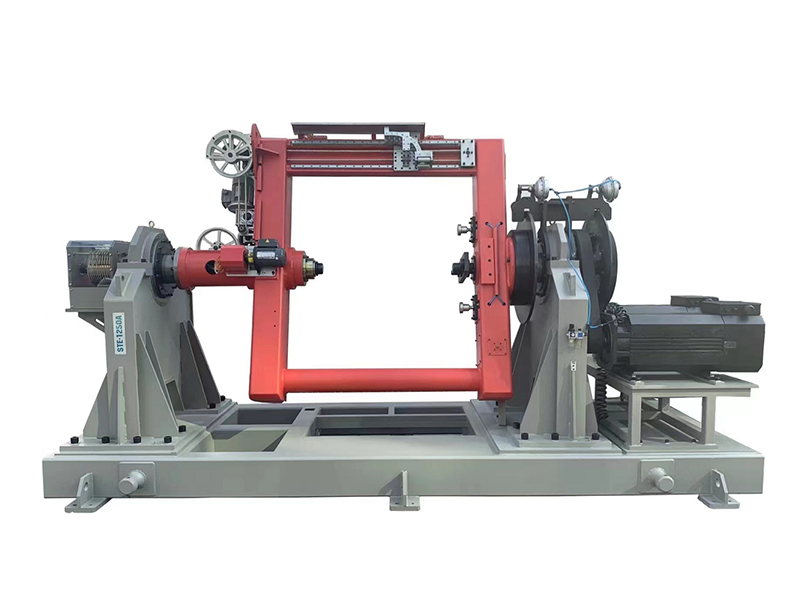

| 6 | Ø1250mm Frame type single twister | 1 set | |

| 7 | Main electric cabinet | 1 set | |

| 8 | Air conditioner for cabinet | 1 set | |

| 9 | Filler stand | 1 set | 8 heads |

| 10 | Lubrication system for Single twist | 1 set | |

| 11 | Lubrication system for taping machine | 1 set | |

| 12 | Automatic bearing temperature sensing system | 1 set | |

| 13 | Forming mould | 1 set | Commissioning |

| 14 | Spare tools | 1 set | Production |

| 15 | Coating: a. RAL5015 b. RAL7035 c.RAL6017 d. RAL5023 e. sample color provided by the customer or based on customer demand. | ||

| 16 | Operation direction:A. From left to right ; B. From right to left | ||

| 17 | Bobbin of 560 and 630mm, the customer provide the bobbin drawing. | ||

Main parameters

| Applicable core wire | Ø0.6-Ø5.0mm (flexible insulation wire: 0.50mm²-6.0mm²) (stranded wire: Max. 6.0mm²) |

| Twisting output diameter | MAX. Ø30.0mm |

| Range of cable lay | 30mm-600mm stepless regulation |

| Take-up bobbin diameter | Ø1250mm |

| Tape specification | |

| Pore diameter | Ø76mm |

| Tape diameter | Ø500mm |

| Width range | 10mm-40mm |

| Applicable materials | Cotton paper, Nylar tape, Aluminum foil tape, Polyester tape |

| Rotation speed of taping machine | Max. 2500 rpm 2000rpm when production |

| Rotation speed of single-twisting machine | Max. 500rpm ( dynamic balance) 400rpm when production |

| Direction | left, right (“S”, “Z”); can be reversed |