0

Sets Machines Produced Per Year

0

%

Package Coverage On Machine

7*

0

Expert Services

0

+

Years Of Product R&D Experience

0

+

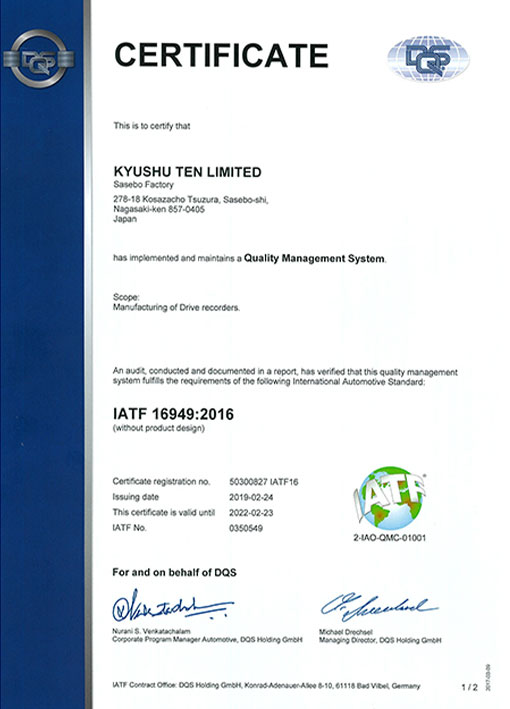

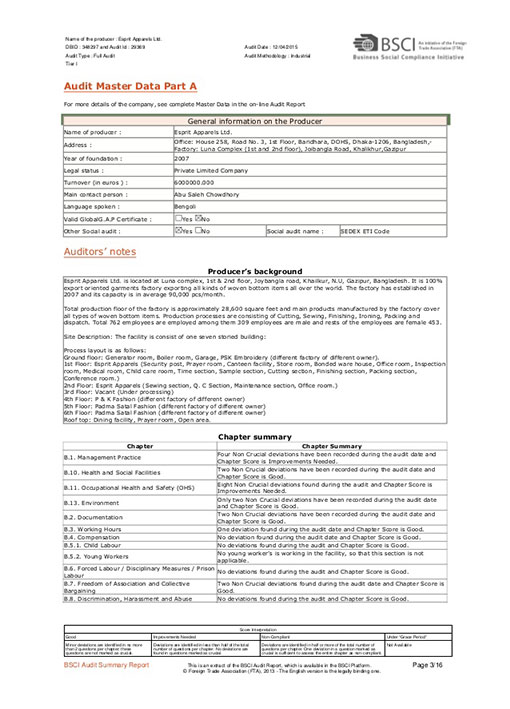

Quality Control Items